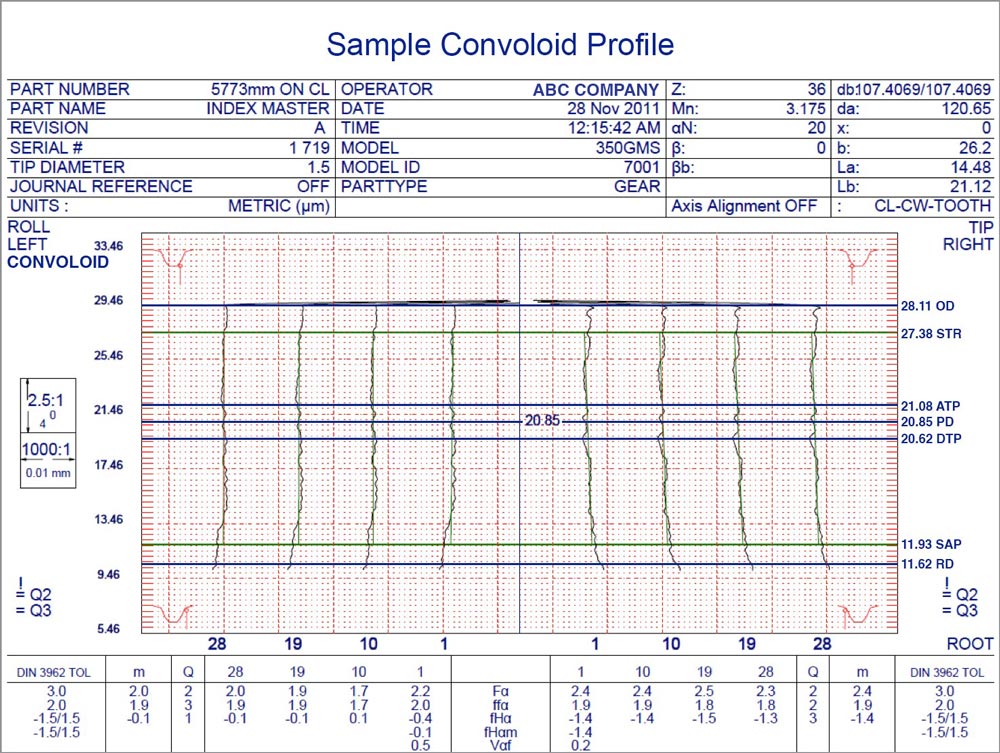

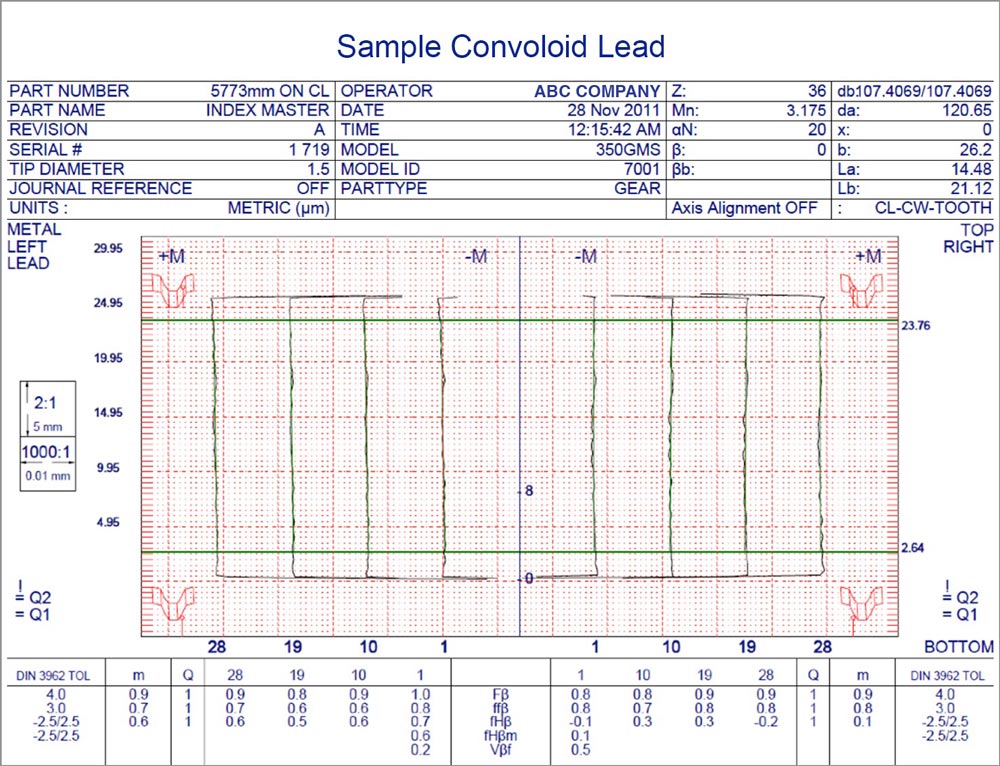

The tooth forms for Convoloid gears are different than those for equivalent involutes and although these differences are subtle they produce very powerful results when power density and surface condition factors are the performance metrics. Manufacturing operational sequences closely follow those of involutes and tolerances and material allowances also closely follow those practices of involute gearing. Hobbing, shaping, gear tooth grinding, skiving and other well established manufacturing processes are common with Convoloids. Inspection techniques are very similar to those of involutes and gear accuracy classification can use the same parameters, limits, ranges, and identification as those for involute gears. Lead modifications, crown of various types, tip relief, root relief, can all be designed into Convoloid gearing pairs and measured appropriately. The general classification accuracy of Convoloid gears can be described using world recognized standards including AGMA, ISO, JIS, DIN, etc.

Manufacturing & Inspection